Electrical steel, also known as silicon steel, is an iron alloy with silicon as the primary additive. This material is used in electromagnetic devices to provide a low reluctance and low loss path for the magnetic flux.

Grain-Oriented vs. Non-Oriented

There are two main types of fully processed electrical steels: grain-oriented (GO) and non-oriented (NO).

Grain-Oriented (GO) Steel: Exhibits optimal magnetic behavior in one direction. This type is primarily used in transformers, where high magnetic efficiency is crucial. The manufacturing process is complex and costly due to the need for precise grain orientation, necessitating performance analysis to justify the additional cost associated with using GO steel.

Non-Oriented (NO) Steel: Features nearly isotropic magnetic properties, making it suitable for applications like motors and generators that require multidirectional magnetization.

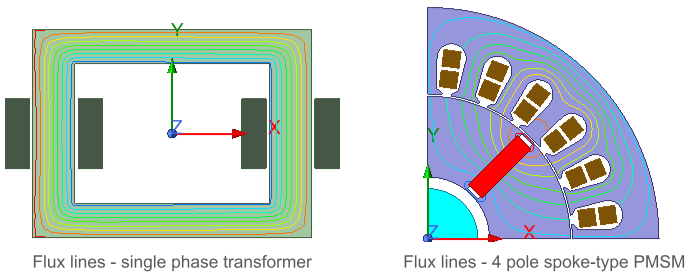

The typical flux lines in transformers and motors/generators, illustrated below, show why rotating machines need multidirectional magnetization and transformers benefit from the unidirectional magnetization provided by GO steels. GO electrical steels may have better magnetic properties in the rolling direction (parallel to the direction in which the steel was rolled during manufacturing, also known as the longitudinal direction). The transverse direction, perpendicular to the rolling direction, runs across the width of the rolled sheet.

These orientations are important because the properties of electrical steel, such as magnetic permeability and core loss, can vary depending on the material’s orientation relative to the rolling direction.

In this article, we dive into the commonly used material designations for non-oriented electrical steels, focusing on how they are graded.

Material Designations

The designation of electrical steels follows specific standards that reveal important details like thickness, core loss, and processing type.

AISI and ASTM Standards

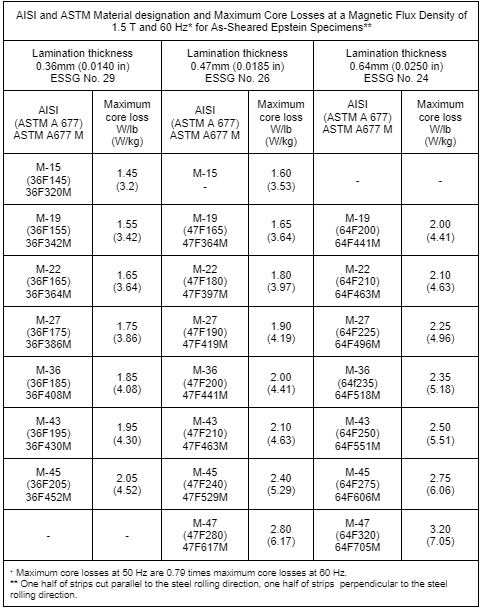

Initially, each producer of electrical steel had unique trade names for their products, leading to confusion. The American Iron and Steel Institute (AISI) addressed this by creating a type number system based on maximum allowable core loss, a key factor for electrical efficiency. This designation uses an “M” for magnetic material followed by a number. Originally, these numbers reflected approximately ten times the core loss in watts per pound for a specific thickness (29 gauge), tested under standard conditions (15 kilogausses and 60 hertz).

Though this direct association is less relevant now due to advancements in electrical steels, the type numbers still represent different grades and their relative core losses.

The American Society for Testing and Materials (ASTM) standards closely mirror AISI’s system. ASTM 667, for example, uses the following nomenclature: the first number is 100 times the nominal thickness in millimeters, followed by an “F” indicating the material is fully processed. The number after “F” is 100 times the maximum specific total loss in watts per pound at 1.5 Tesla and 60 Hz. ASTM 667M follows a similar pattern but uses metric units, with the number after “F” being 100 times the maximum specific total loss in watts per kilogram. The “M” denotes metric units for specific loss.

Navigating Multiple Standards in Electrical Steel Designations

Having various standards can lead to confusion and complexity. Therefore, design engineers must be familiar with different material designations. Let’s explore a few standards beyond AISI and ASTM.

BS EN 10106 Standard

This European Standard specifies the grades of cold-rolled non-oriented electrical steel sheets and strips in nominal thicknesses of 0.35 mm, 0.50 mm, 0.65 mm, and 1.00 mm. The steel naming follows this order:

(1)The letter M for electrical steel; (2)One hundred times the maximum specific total loss at 1.5 T and 50 Hz, in watts per kilogram; (3)One hundred times the nominal thickness in millimeters; (4)The letter A for fully processed non-oriented electrical sheet or strip.

Example: M250-35A indicates electrical non-oriented steel with a maximum specific total loss of 2.50 W/kg at 1.5 T and 50 Hz, and a nominal thickness of 0.35 mm, fully processed.

IEC 60404-8-4 Standard

Similar to BS EN 10106, this standard includes an additional identifier for the frequency at which the maximum specific loss is specified, represented as one-tenth of the applied frequency, i.e., 5 or 6 for 50 and 60 Hz respectively.

GB/T 2521.1 Standard

This Chinese standard is similar to BS EN 10106, covering grain non-oriented electrical steel strips in nominal thicknesses of 0.35 mm, 0.50 mm, and 0.65 mm. The steel naming follows this order:

(1)One hundred times the nominal thickness in millimeters; (2)The letter W indicating non-oriented; (3)One hundred times the maximum specific total loss at 1.5 T and 50 Hz, in watts per kilogram.

Example: 50W400 refers to cold-rolled grain non-oriented electrical steel with a nominal thickness of 0.5 mm and a maximum specific total loss of 4.00 W/kg at 1.5 T and 50 Hz.